i) Fitment of soft buffer in ICF designed CBC fitted coaches

ii) Replacement of buffer in conventional coaches

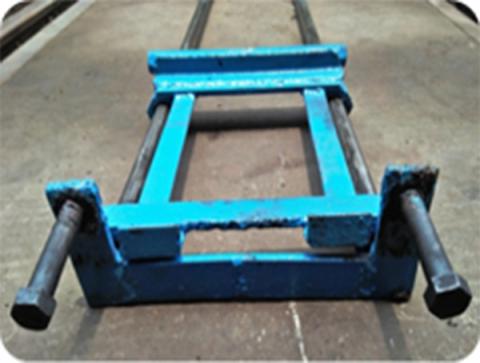

Gadget for lifting of Side Buffers for fitment in coaches

Make: Developed at Coaching Depot, Santragachi, South Eastern Railway

Description:

This rectangular shaped (120”x 14.5”) gadget (shown in picture below) is made up of SS pipes of 28 mm OD,1.5 mm thick with Sliding Table arrangement. This table is provided in such a way that the table with buffer can move freely on the longitudinal pipes of the gadget. There is a fixing arrangement at the ends of ‘A’ to be fixed with the bottom holes (2 nos.) on the head stock where the buffer to be fitted. Handles at the end ‘B’ have been provided for easy lifting of gadget manually. The gadget works as a Class 2 lever with fulcrum at end ‘A’ i.e. the head stock, effort at end ‘B’ and load (buffer) in between to achieve maximum Mechanical Advantage. Thus the gadget works successfully with less man power, time and ensuring safety.

Requirements for fitment of buffer:

i) Gadget for lifting of Side Buffers for fitment in coaches developed at SRC

ii) Box Spanner, Size 36

iii) Manpower-3 persons to be provided

iv) Wooden Skids- 4 nos.

Procedure for fitment of buffer:

Before fitment of buffer in a coach, ensure protection of lines and provide skids on

the lines to avoid rolling of wheels of the coach. Steps for fitment of buffer are mentioned as under:

|

Step-1 |

End ‘A’ of the gadget to be fixed on the bottom holes (2 nos.) on the head stock where the buffer to be fitted . |

|

|

Step-2 |

Fix buffer on Sliding Table provided on the gadget |

|

|

Step-3 |

Push the table manually from end ‘B’’ to end ‘A’ |

|

|

Step-4 |

Simultaneously end ‘B’ of the Gadget is to be lifted gradually with the help of handles provided. |

|

|

Step-5 |

Place the buffer on the head stock and fix two upper Nylock nut bolts provided in the head stock to hold the buffer securely. |

|

|

Step-6 |

Release the gadget |

|

|

Step-7 |

Fix the lower two Nylock nut bolts. Ensure proper tightness of all Nylock nut bolts. |

|

- The gadget is simple and portable.

- Fitment of buffer is easy because of its mechanical advantage always more than 1.

- Only 3 staffs instead of 9 staffs earlier are required for fitment of buffer.

- Fitment time is also very less. 3 staffs can easily fit a buffer within 10 minutes.

- It is very safe as there is no chance of dropping of buffer during fitment.