Keywords for search(use comma / separator):

Compressed Air, Electric energy, Air Dryers, blow guns, Isolating valve

Location, Zonal Railway/Division/Units where used :

DMW/Patiala

Contact Person:

Sh. S.K.Babbar, Dy.CME/Plant

Where can it be used:

Generation & Supply of Compressed Air.

Brief description:

DMW has saved 942120 Kwh of electricity (resulting in 35.39% saving of electric energy) during 2018-19 in generation & supply of compressed air by adopting following measures:

- Under-ground supply pipeline has been replaced with overhead pipeline.

- Dedicated team has been nominated to deduct & address leakages.

- Voltage Stabilizers have been replaced with Phase Reversal/ Phase Failure Protection Relays, duly modifying the electrical circuit of compressors.

- Surplus delivery points of compressed air have been plugged in various shops.

- Two nos. Air Dryers (Cap. 1500 CFM each) have been commissioned to improve quality of compressed air.

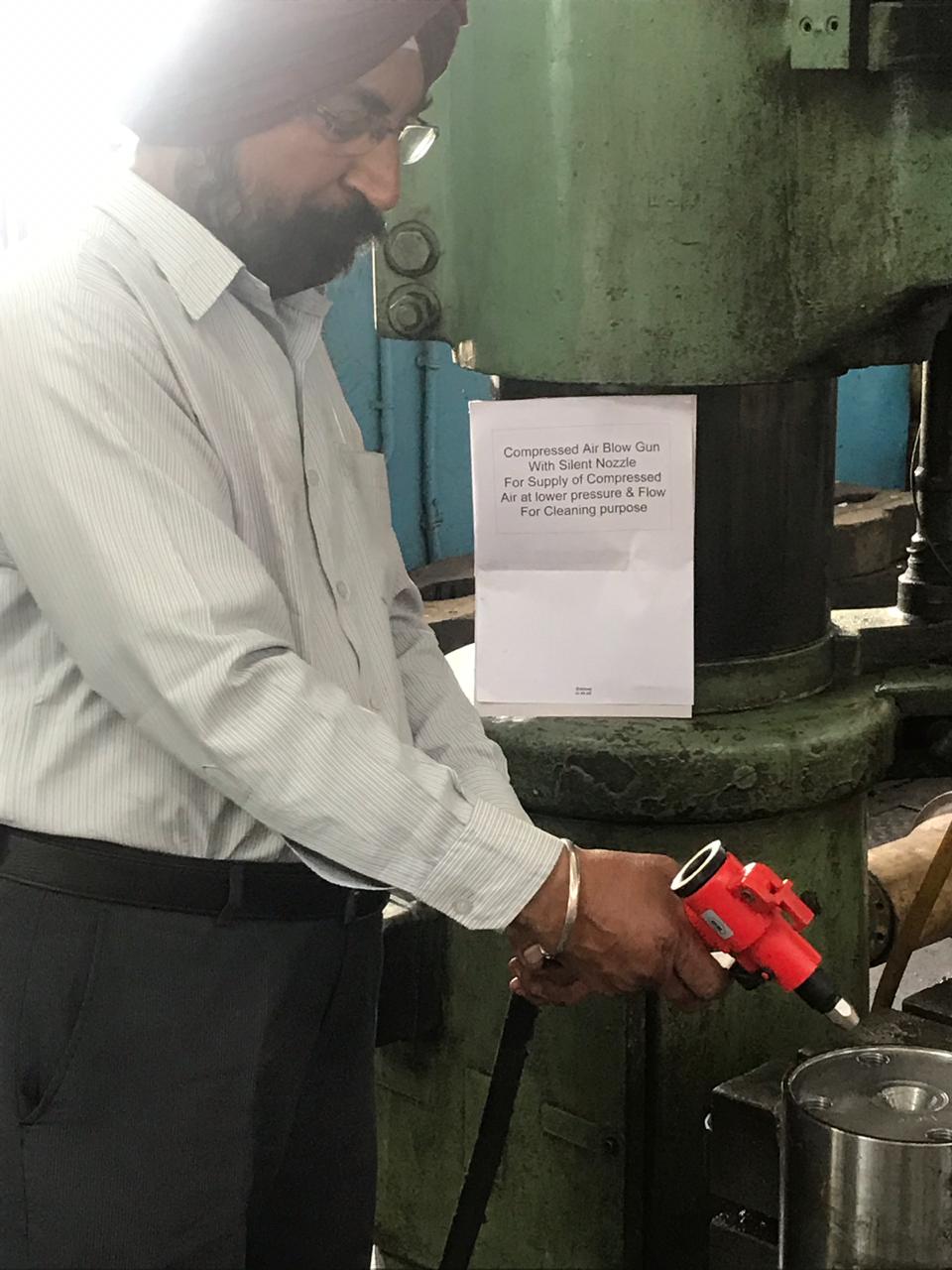

- Air blow guns with silent Nozzle are being used during maintenance and on service points.

- Isolating valve has been provided between HMS & PPS to control supply of compressed air.

- Use of baby compressors for intermittent supply.

Above comprehensive measures resulted in saving of Rs. 79 Lakhs in generation & supply of compressed air.